How Much Does an Air Dome Cost?

Visit our Dome Store for current prices on dome components.

Dome packages start at $12 per square foot. Price depends on dome size, doors, lights, and HVAC. At minimum, a dome consists of a fabric envelope, inflation units, and a few doors (emergency, revolving, handicap-accessible, and/or cargo air locks).

Need 3D renderings of your potential dome project?

We can produce these starting at $1,000!

Dome Installation - Cost and Timeline

Dome installations require our dome supervisory team, manual laborers, some heavy equipment (typically a 10k fork lift), an electrician to hook up lights and blowers, and an HVAC technician for mechanical unit start-up. Small domes can be installed in as few as 4 days, whereas larger domes may take several weeks. Total dome package installation cost is simply a function of time: how long the supervisors, equipment, manual labor, and other resources are needed, multiplied by their rates. Dome owners can reduce the cost of installation by gathering volunteers to help offset manual labor costs, and by procuring heavy equipment themselves.

EXAMPLE COST OF 7 DAY DOME INSTALLATION: $74,000 for full dome installation team, electrician and HVAC technician, and equipment rental; owner provides manual labor / volunteers to assist in fabric roll-out.

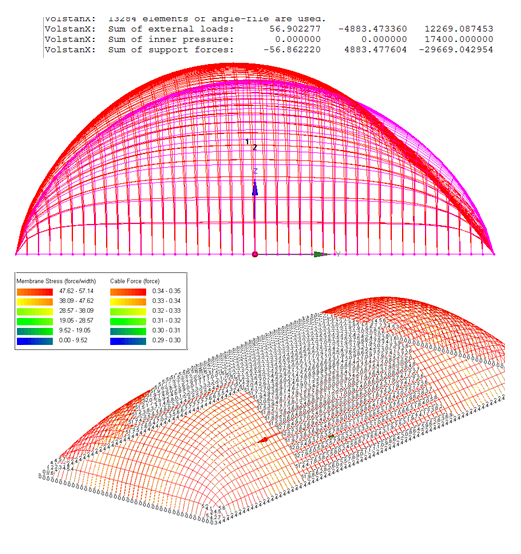

Design and Engineering

Air domes adhere to several codes, including IBC and ASCE 55-16. Your dome project will likely require a set of permit drawings to obtain a permit, and licensed engineers to stamp every element of your dome project. Dome structural and mechanical engineering typically costs around $20,000. Our engineering teams are licensed in all 50 states and in 42 countries. Additional engineering, such as civil, electrical engineering and architectural services will be required; cost depends on your site requirements, local codes, etc.

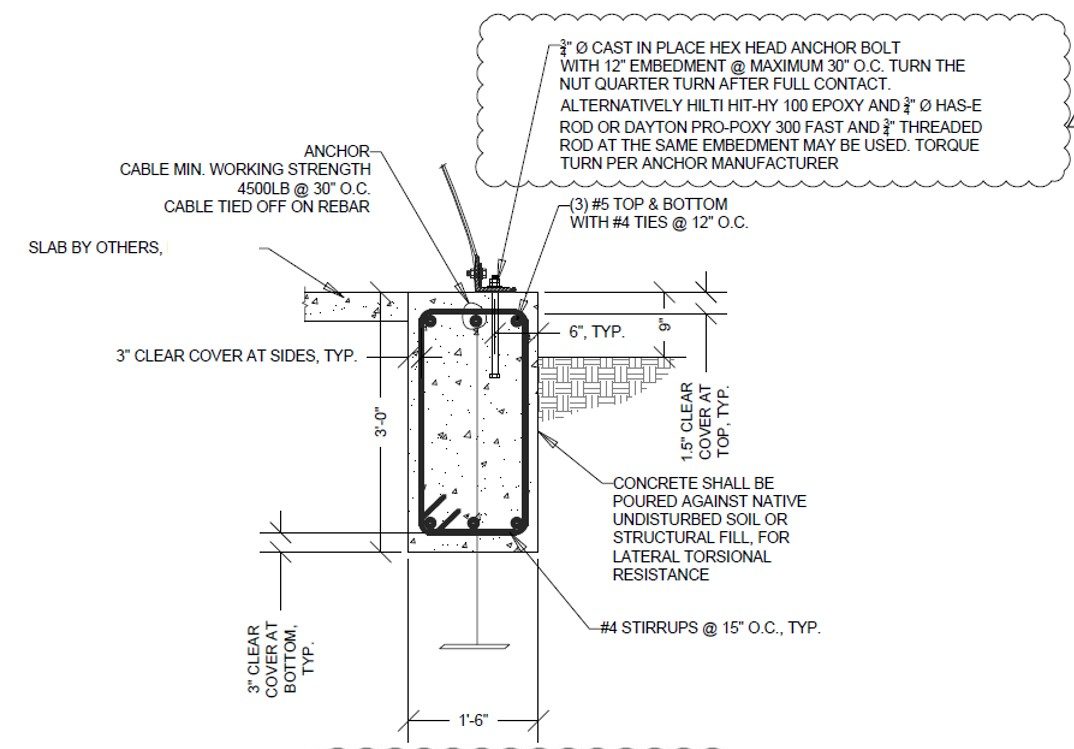

Dome Foundation

Domes are anchored into the ground to counteract lateral and uplift forces, and to maintain the air seal. Most domes are anchored down by angle iron on a grade-beam concrete foundation, but some temporary domes are anchored using earth anchors, helical anchors, sand bags, or an aluminum channel system. Cost of the foundation depends on its design, and the design depends on the condition/holding capacity of your soil, your local wind codes, and costs of construction materials and labor. While we can provide a rough estimates, engineering is required to determine the foundation you will need and its associated cost.

EXAMPLE FOUNDATION INSTALLATION COST: For a 100,000 sq.ft. dome being installed in Michigan, our hybrid Grade Beam - Earth Anchor foundation is estimated to cost $350,000.

Ongoing Operational Expenses

How much does it cost to operate a dome? Cost of running inflation units alone is typically between $0.10-0.20 per sq.ft. per year. Utility costs including lights, heating and cooling can rise to $0.50 - $1.50 per square foot per year. Just like utilities in a home, costs vary widely depending on the type of dome you have, climate/weather, usage, utility rates, etc. HVAC unit maintenance is the same as with any other type of commercial building, and the cost of maintaining the rest of the dome is minimal. Our North American based service teams can help to perform regular maintenance and fix damage to the dome or components.

Perfect Safety Record

A price can't be put on the safety of dome occupants. Broadwell is the only air dome company in the world with a perfect safety record. Our domes are safer because we use stronger materials than most other dome companies, and we engineer our domes with safety as the first priority.

PROJECT ROLES & RESPONSIBILITIES

Overview of typical parties involved in a Broadwell Air Dome project:

Broadwell: Providing dome and components; consultation.

Structural Engineer: Procured by Broadwell for dome structural and foundation structural calculations, and basic drawings. Other project structural engineering to be procured by Buyer.

Mechanical Engineer: Procured by Broadwell for dome HVAC calculations. Other project mechanical engineering to be procured by Buyer.

Installation Team: Consultation provided and resources recommended by Broadwell; Installation resources contract directly with Buyer. This team installs (where applicable) the fabric, cable harness, doors, lights, and insulation. Typically up to 50 manual laborers will be needed for fabric and cable harness roll-out.

Electrical Engineer: Procured by Buyer, if needed, to create electrical drawings for permitting.

Architect: Procured by Buyer. To do local code review to ensure all codes are being met in dome design and scope; creates full site documents, and a permitting set (if required) to account for all building codes, life safety and fire codes, etc.

Local General Contractor: Procured by Buyer to project manage and oversee foundation installation, site work, component installation; works with dome installation team to prep site, procure equipment, etc. Applies for permits, if required.

Local Code Officials: Architect and General Contractor to communicate with local building code officials, fire code officials, and any other parties early on in dome design process to ensure dome scope meets all required codes.

Local licensed electrician: Procured by Buyer (often by Buyer’s GC) to connect lights, HVAC units, all other site electrical needs.

Local HVAC technician: Procured by Buyer (often by Buyer’s GC) for HVAC unit hookup, ongoing service and maintenance.

Natural Gas Hookup: Procured by Buyer (often by Buyer’s GC) for gas hookup of backup blower engine/generator and gas heaters (if applicable).

Dome Operator/Maintenance Team: Procured by Buyer, for ongoing operation of dome, regular inspections, minor maintenance and repairs.

The Purchase Process

Step 1: Initial Scope Discussion

Our initial discussion will determine the scope of your project so that we can determine ball-park costs and identify next steps. Basic questions include:

- What will be the size and use of your dome?

- What is your approximate occupancy inside the dome?

- Will you need to have large vehicles enter and exit the dome?

- What is your timeline for needing the dome operational?

- Is funding in place? (We have several funding options.)

- Do you have an architect?

Step 2: Design and Engineering

In order to fully determine the cost of your dome package, we need to design and engineer the dome. Your inflation system is designed to take into account the force loads acting on the dome based upon your local wind and snow loads. If you need heating or cooling, the HVAC system is designed by looking at your local weather and identifying the heating or cooling needed to achieve internal design temperatures. Amount and type of lights are identified via a photo-metric lighting design to achieve desired foot-candle coverage. Your foundation is designed to meet force loads required and takes into account the soil holding capacity of your site. After we do the full engineering, we are able to finalize the dome package scope, and we can solidify the dome price along with its full installation.

Step 3: Dome Production and Site Work

After you sign off on the final dome design, the production of the dome and its components will begin. While the dome and its components are being produced, installation of the dome foundation and other site work will commence.

Step 4: Completed Production and Transportation

When the dome is completed, the entire dome package will be transported to the final installation site.

Step 5: Dome is Installed

Your dome is installed by our expert installers! Installation can take as few as 2 days for small domes, and up to several weeks for larger domes and complex installations.